How Does a Spray Bottle Work? Mechanisms Explained!

When you press the trigger on a spray bottle, you activate a small pump that’s connected by a dip tube to the liquid reservoir. This pump draws liquid up through the tube.

As you pull the trigger, it lifts a piston, opening a valve that allows the liquid to flow. Releasing the trigger causes a spring to reset the piston, sealing the valve to halt the flow and forcing air into the chamber, building pressure.

The pressurized liquid is then forced through a meticulously designed nozzle, which atomizes the liquid into a fine spray. Exploring further will enhance your understanding of its versatile applications.

Key Takeaways

Understanding Spray Bottle

A spray bottle is a container designed to emit liquids in a fine, mist-like spray. It typically consists of a plastic bottle body, a trigger lever, and a nozzle that can be adjusted to control the spray’s intensity and pattern. A continuous spray bottle overview highlights its ability to release a steady, even mist with minimal effort, making it ideal for applications like hairstyling, cleaning, and plant care. Unlike traditional spray bottles, which require repeated pumping, continuous spray bottles use a pressurized mechanism to maintain a consistent spray. This design enhances user convenience and reduces hand fatigue during extended use.

Commonly used for cleaning products, personal care items, and gardening applications, spray bottles are valued for their ease of use and efficiency in dispersing fluids evenly.

Understanding the Basic Components

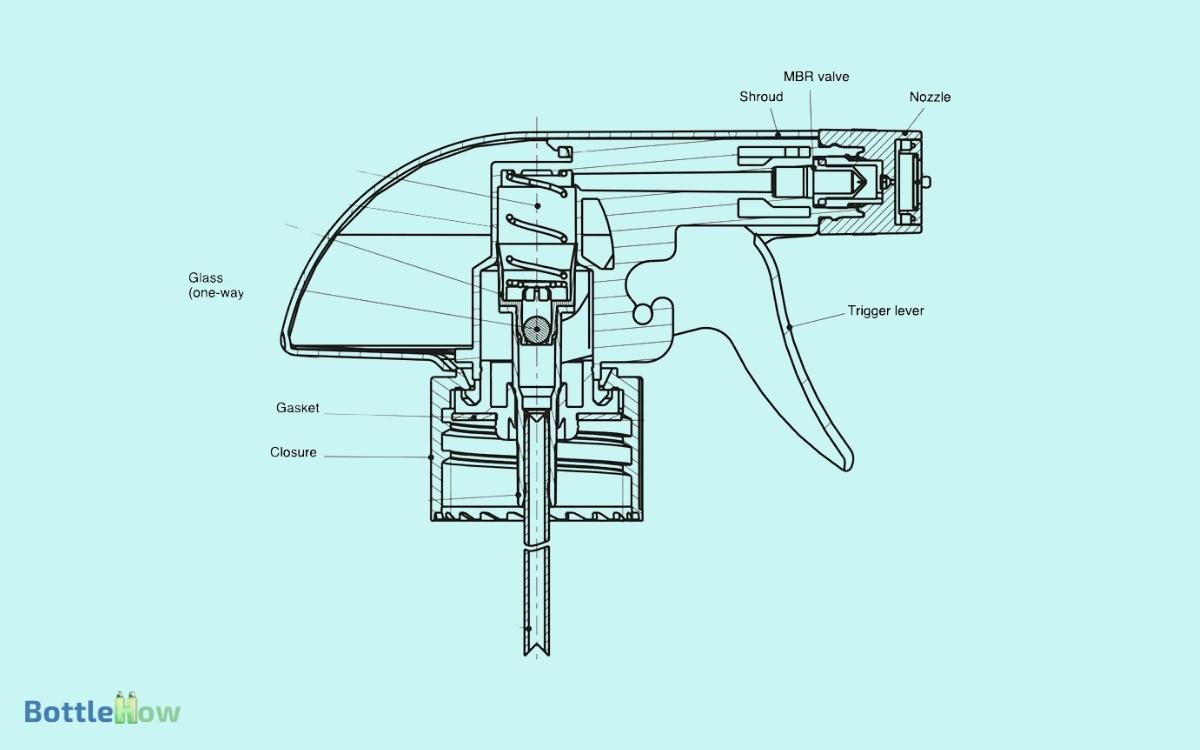

To understand how a spray bottle functions, it’s important to first identify its essential components:

- The trigger lever,

- Pump mechanism,

- Nozzle.

When you squeeze the trigger lever, it activates the pump mechanism. This pump is essential as it draws the liquid up through a dip tube, which we’ll discuss later. The precision of this mechanism guarantees a consistent flow of fluid each time it’s activated.

The nozzle then plays a pivotal role. It’s designed to atomize the liquid, transforming it into a fine mist. This process depends on the nozzle’s configuration, which controls the spray pattern and intensity.

Understanding these components helps you effectively maintain and operate spray bottles, ensuring peak performance in tasks that support cleanliness and hygiene.

The Role of the Reservoir

Understanding the basic components sets the stage for exploring how the reservoir in a spray bottle holds and supplies the liquid for spraying.

The reservoir, typically a cylindrical chamber, is essential for storing the liquid until you’re ready to use it. It’s designed to withstand the pressure changes that occur during the operation of the spray bottle, ensuring a steady supply of liquid to the pump mechanism.

The material of the reservoir, often a robust plastic like polyethylene, is selected for its durability and chemical resistance, which prevents degradation from various liquids.

Additionally, the reservoir’s capacity determines how much liquid can be efficiently dispensed before needing a refill, optimizing your ability to serve effectively and continuously without frequent interruptions.

How the Trigger Mechanism Functions

When you press the trigger on a spray bottle, it activates a complex mechanism that controls the release of liquid.

This mechanism is essential for ensuring a measured and efficient dispersal of fluids, helping you serve effectively in tasks ranging from cleaning to gardening.

Here’s a breakdown of its components:

- Piston: The trigger’s pull lifts the piston, creating a vacuum.

- Spring: This component returns the piston to its original position, readying the system for the next press.

- Valve: It opens to allow liquid flow when the piston moves, and closes to seal the passage post-spray.

Understanding these elements enhances your ability to maintain and troubleshoot the bottle, ensuring continuous service without interruption.

The Science Behind Pressure Buildup

Exploring further, let’s examine how the mechanism you just activated causes pressure to build up inside the spray bottle.

When you press the trigger, it actuates a small pump connected to a tube that extends to the bottom of the bottle. This pump displaces air inside the tube, creating a vacuum that draws liquid upward from the reservoir.

As you continue to squeeze, the pump forces this liquid into a small chamber where the volume is markedly less than the tube. This reduction in volume increases the pressure within the chamber.

Each subsequent press compounds the air pressure over the liquid, propelling it towards the nozzle. This process is essential for ensuring that the spray bottle functions efficiently, serving your needs effectively in various applications like cleaning or gardening.

Spray Nozzle Design Explained

The spray nozzle’s design greatly influences the mist quality and spray pattern you experience.

In crafting an effective nozzle, engineers focus on several key elements:

- Orifice Diameter: The size of the nozzle opening dictates the flow rate and droplet size. A smaller orifice produces a finer mist, which is important for applications requiring gentle, even distribution.

- Nozzle Geometry: The shape of the nozzle affects the spray angle and coverage area. Conical nozzles, for instance, are designed to maximize spread.

- Material Construction: Nozzles made from durable materials like brass or stainless steel offer longevity and consistent performance, essential for frequent use.

Understanding these aspects, you can better appreciate how meticulous design serves to meet diverse needs effectively.

Variations and Uses of Spray Bottles

Spray bottles vary widely in design and function, catering specifically to applications ranging from household cleaning to agricultural spraying.

You’ll find them engineered with differing spray mechanisms trigger sprayers for direct, manual control and aerosol-driven sprayers for a finer mist.

The choice of material, from robust plastics to corrosion-resistant metals, directly influences their durability and suitability for various chemicals.

In healthcare, for instance, spray bottles deliver sanitizing agents precisely where needed, minimizing waste and enhancing efficiency. In agriculture, they’re indispensable for the even distribution of pesticides.

Understanding the specific requirements of each application guarantees you select a bottle that not only serves effectively but also withstands the rigors of its intended use, embodying a commitment to both function and stewardship.

Conclusion

To sum up, your understanding of spray bottles now encompasses their core components—from the reservoir to the intricately designed nozzle.

For instance, imagine you’re misting orchids with a fine spray; this action is made efficient by the precise pressure mechanics and nozzle design that atomize liquid into fine droplets.

This technical insight not only enhances your grasp of daily tools but also empowers you to optimize their use across various applications, from gardening to household cleaning.